Guangdong Headway Electric Heat Components Co., Ltd.

Guangdong Headway Electric Heat Components Co., Ltd. is a specialized manufacturer integrating the R&D and production of electric heating tubes and various electric heating components. Its products are primarily used in appliances such as air conditioners, refrigerators, washing machines, electric water heaters, dishwashers, ovens, and solar water heaters. It has collaborated with many well-known listed electrical appliance companies in China. Founded in 2000, the company has set up production bases in Shunde, Guangdong, and Wuhu, Anhui. Boasting formidable strength, the company exhibits robust strengths in R&D and manufacturing.

In 2022, Airboss constructed an intelligent air compressor station at Headway’s production base in Shunde, Guangdong. This station comprises two 132KW energy-saving screw air compressors independently developed by Airboss, along with corresponding compressed air purification equipment. Additionally, the intelligent air compressor station features a waste heat recovery function, which allows the recovered heat to be used in production processes, enabling the operating energy efficiency data of the air compressor station to reach the first-class level.

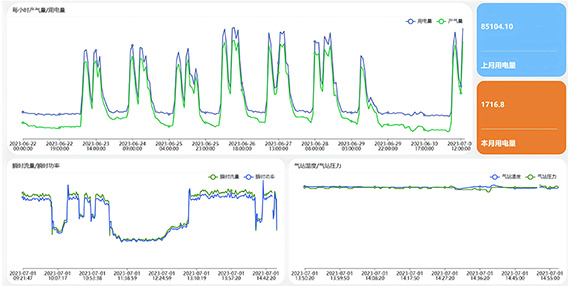

Intelligent Air Compressor Station Operating System

I. Analysis of the user's air compressor station operating parameters and characteristics

1. Operating pressure, air consumption, and runtime: The air compressor station operates at a pressure of 0.74 MPa, with an air consumption of approximately 40 m³/min, and runs 24 hours a day.

2. Variation in air consumption: Due to significant fluctuations in the customer's production capacity between day and night, the air consumption varies greatly. This presents a challenge for the operational management of the air compressor station, requiring adjusting the operating status based on real-time air consumption to maintain energy-saving and efficient operation.

II. Airboss' Measurement and Monitoring Measures

1.Measurement with vortex flowmeter: A vortex flowmeter installed on the main pipeline at the rear end of the compressed air purification equipment can accurately measure the flow of compressed air and provide data support for calculating the air-to-power ratio. Simultaneously, real-time monitoring of the flow allows for the understanding of changes in air consumption and provides a basis for optimizing the operation of the air compressor station, with the measured comprehensive gas-to-power ratio standing at approximately 0.11 kWh/m³.

2.IoT system monitoring: Airboss independently operates the intelligent air compressor station and monitors operational data changes 24 hours a day in real time via the IoT system. The application of the IoT system allows the operational status of the air compressor station to be monitored anytime and anywhere, enabling timely detection and handling of potential issues. This real-time monitoring enhances the operational reliability of the air compressor station and ensures that the system consistently operates at optimal efficiency.

Related news

Case Study2024-10-09

Hunan Shanshan New Energy Co., Ltd.

2024-10-09

Dongguan Weiyuan Hardware Co., Ltd.

2024-10-09