"Zero" Pressure Loss Three-in-one Purifier

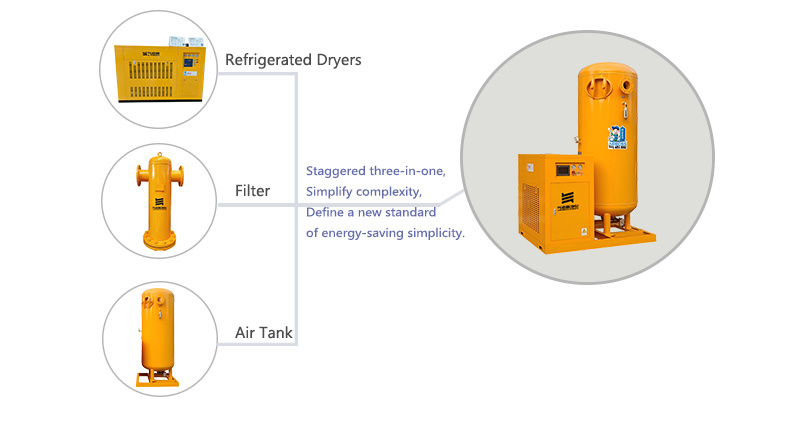

The "zero" pressure loss three-in-one purifier is a new high-end post-treatment system for compressed air. It is not just a combination of one device.

Classify:

Key words:

"Zero" Pressure Loss Three-in-one Purifier

- Features

- Specification

-

The "zero" pressure loss three-in-one purifier is a new high-end post-treatment system for compressed air. It is not just a combination of one device. It highly integrates the compressed air purification system at the back end of the air compressor with the air storage tank. By changing its internal gas flow direction: air compressor → oil-water separator → refrigeration dryer → air storage tank → refrigeration dryer → high-efficiency oil remover → gas consumption unit, the system pressure loss is reduced by more than 70%. The compressed air processed by the "zero" pressure loss three-in-one purifier can have a pressure dew point of 2 to -10 °C, a dust content lower than 0.01 μm, and an oil content lower than 0.01 ppm. It can be directly applied to most industrial occasions.

Working conditions

Ambient temperature: ≤40℃ (air-cooled), ≤56℃ (water-cooled)

Cooling water temperature: ≤32℃ (water-cooled)

Maximum inlet temperature: ≤80℃

Rated inlet temperature: ≤52℃

Pressure dew point: 2 - 10℃

Maximum pressure: 0.8/1.0 MPa (optional if exceeding this pressure)

Rated pressure: 0.7 MPa

Dust removal precision: ≤0.01 ppm

Oil removal precision: ≤0.01 ppm

System pressure loss: ≤0.01 MPa

-

Specification

Model

Volume of Air Tank(m3)

Standard Processing Capacity

(m3/min)Power Supply

Refrigeration Power (KW)

Filter Size

Filtration Form

Inlet and Outlet Sizes

Overall Machine Size(mm)

Length TD-1-012GE

13.8

2.6

-040L

1550

1

DN80

3① 380V 50Hz

Fully built-in

TD-1-015GF

17

3

-040L

1550

TD-2-020GF(W)

24.5

3.6

-060L

1750

2

DN100

TD-2-025GF(W)

28

4.1

-060L

1850

TD-2-030GF(W)

33

4.8

-060L

1850

TD-2-040GF(W)

45

6.9

-080L

2150

DN 125

TD-3-040GF(W)

45

6.9

-080L

2400

3

TD-3-050GF(W)

55

7.9

-120L

2400

DN 125

TD-3-060GF(W)

65

8.9

-120L

2400

TD-4-080GF(W)

4

88

10.4

-160L

2450

DN 150

TD-5-100GF(W)

5

110

16

-200L

2850

Notes

1.The sizes of gas tanks and the processing capacities of refrigeration dryers in the above table are only recommended configurations, and can be selectively matched according to the actual requirements of users.

2.The size of the refrigeration dryer needs to be selected according to the on-site working conditions (inlet pressure, inlet temperature, etc.). For details, please refer to the "Selection Table for Three-in-One Purifiers".

3.The built-in filters in the entire series have increased processing capacity and can effectively reduce system pressure loss.

4.Customization is acceptable for volumes, processing capacities, and pressures exceeding the specifications in the above table. Special materials such as stainless steel can also be customized.

5.Standard pressures: 0.8 MPa and 1.0 MPa (special customization for pressures exceeding this).

Application cases

Oil Injected Rotary Screw Compressors

Oil Injected Rotary Screw Compressors

Oil Injected Rotary Screw Compressors

Oil Injected Rotary Screw Compressors

Oil Injected Rotary Screw Compressors

Oil Injected Rotary Screw Compressors

Oil Injected Rotary Screw Compressors

Oil Injected Rotary Screw Compressors

Advantage

Application description

Rebar is the common name for hot rolled ribbed steel bars. The grade of ordinary hot-rolled steel bar is composed of HRB and the minimum yield point of the grade. H, R, and B are the first letters of the three words Hotrolled, Ribbed, and Bars respectively. Hot-rolled ribbed steel bars are divided into three grades: Grade II HRB335 (the old grade is 20MnSi), Grade III HRB400 (the old grades are 20MnSiV, 20MnSiNb, 20Mnti), and Grade IV HRB500.

Factory description

Rebar is the common name for hot rolled ribbed steel bars. The grade of ordinary hot-rolled steel bar is composed of HRB and the minimum yield point of the grade. H, R, and B are the first letters of the three words Hotrolled, Ribbed, and Bars respectively. Hot-rolled ribbed steel bars are divided into three grades: Grade II HRB335 (the old grade is 20MnSi), Grade III HRB400 (the old grades are 20MnSiV, 20MnSiNb, 20Mnti), and Grade IV HRB500.

Shipping Packaging

Rebar is the common name for hot rolled ribbed steel bars. The grade of ordinary hot-rolled steel bar is composed of HRB and the minimum yield point of the grade. H, R, and B are the first letters of the three words Hotrolled, Ribbed, and Bars respectively. Hot-rolled ribbed steel bars are divided into three grades: Grade II HRB335 (the old grade is 20MnSi), Grade III HRB400 (the old grades are 20MnSiV, 20MnSiNb, 20Mnti), and Grade IV HRB500.

Why Choose Us?

1)The products can be made completely according to the customer's requirements, and we have our own factory. 2)High quality product and good price. 3)Good Pre-sale、on sale and after sales service. 4)Short delivery time. 5)Exported all over the world, with rich experience.

FAQ

Q:I want a specific size or color. Can I get my color coated steel customized?

Yes. Customization is available. You can choose the color or pattern, size (length, width, thickness, weight, etc.), paints, shape, etc. We offer coils and sheets, as well as further processing services, such as logo printing, etc. Please send us your requirements, we will meet your requirements.

Q: Are we a trader or a manufacturer?

A: We are a manufacturer and have our own factory.

Q: How to pack?

A: Can be packaged according to customer's needs

Q: How long is your delivery time?

A: If the goods are in stock, generally about 25-30days if the goods are not in stock, according to the quantity.

Related Products