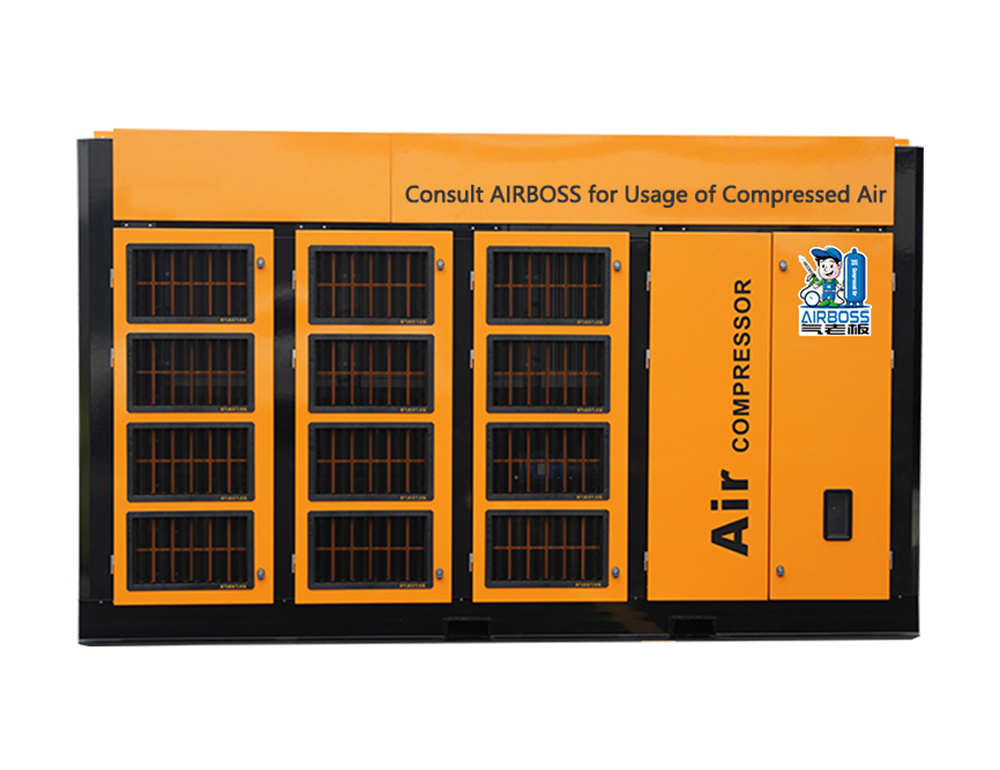

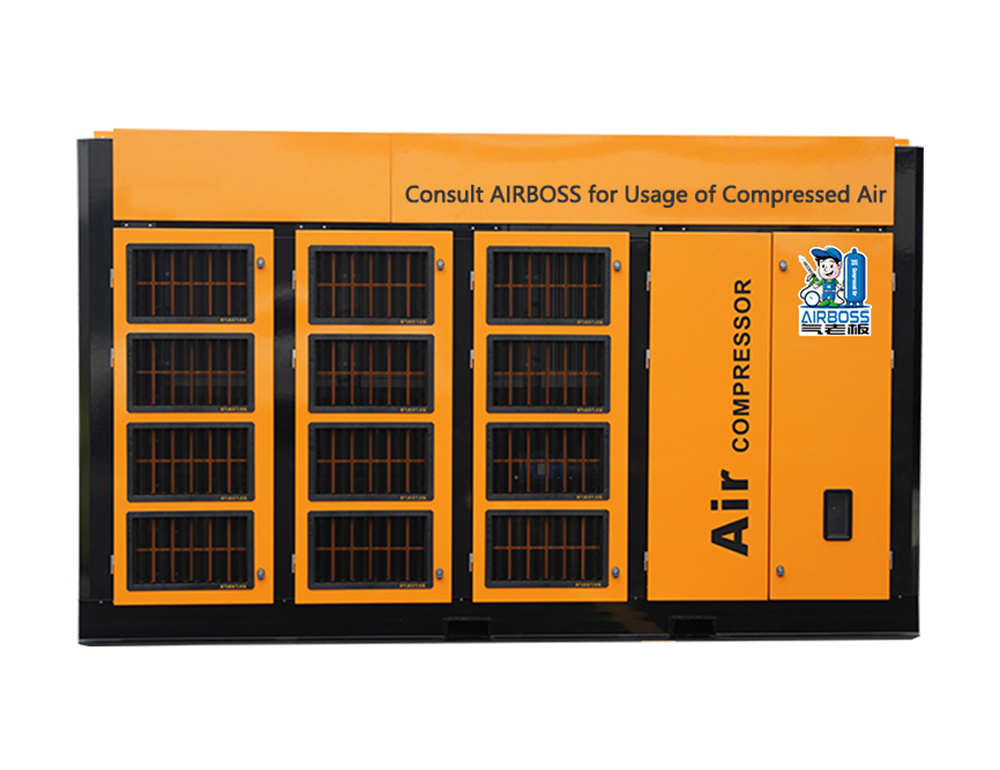

Oil Injected Rotary Screw Compressors

Permanent magnet variable-frequency air compressors use less electric energy to provide more compressed air and a wider capacity modulation range.

Classify:

Key words:

Oil Injected Rotary Screw Compressors

- Features

- Specification

-

Advantages of permanent magnet variable-frequency air compressors

Permanent magnet variable-frequency air compressors use less electric energy to provide more compressed air and a wider capacity modulation range. At present, they are new energy-efficient air compressor models. The permanent magnet variable-frequency air compressor saves 15~38% of energy compared to power-frequency air compressors, and 5~10% of energy if compared with common variable-frequency air compressors. Moreover, the more dramatically the compressed air consumption of the system fluctuates, the more significant the energy-efficient effect will be. The most energy-efficient air compressors now are two-stage screw air compressors. They are the most advanced air compression equipment and have high air output, low noise, and low power. By contrast to single-stage screw air compressors, two-stage screw air compressors can save the energy by 50%.

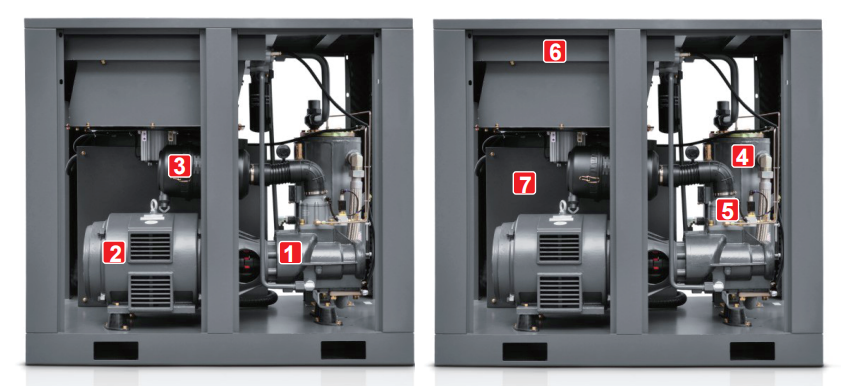

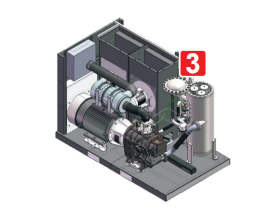

1. An energy-efficient screw host machine

The host machine is of a well-known brand. Thanks to such an excellent machine, the compressor shows excellent performance on the whole.

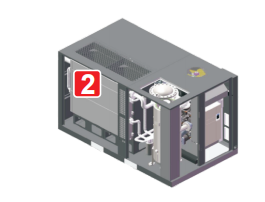

2. An energy-efficient high performance motor

The high-performance motor is customized and provided with SKF heavy-duty bearings, and has an insulation grade F. Compared with like products, the efficiency is improved by 3~5%.3.An energy-efficient oil-air separator element system

With an efficient precision oil-air separator element, the system can effectively lower oil content in the exhaust of the compressed air and the power dissipation of the entire machine set. More particularly, the oil content merely reaches 1~2PPM.

4.A well-designed cooling system

An efficient heavy-duty air intake filter is adopted and ensures the inlet air quality for the compressor and the safety of the host machine. Hence, the service life of such equipment can be significantly improved.

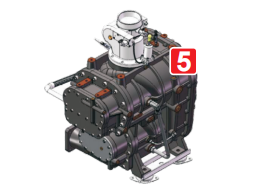

5. An energy-efficient air intake control system

With a customized air inlet valve, air flows can be automatically adjusted in a range of 0~100% based on the system’s compressed air consumption demands, to reduce the corresponding operating cost.

6.An intelligent microcomputer control system

It is a Chinese/English control system easy to operate. This system can automatically run for 24 hours in an unattended condition. Besides, the system can be customized in other languages.

7.A frequency converter

The main electrical elements are all from internationally famous brands and contribute to significantly extending the service life of electrical apparatus.Design

1. An independent air inlet and exhaust channel

Independent air inlet can be achieved for the air filter, the motor, and the electric box. In this way, the heat in the box can be prevented from being sucked into the air filter or the motor and the intake of clean air can be ensured.

2. An efficient multi-step cooler

Stress deformation caused by cold shrinkage and thermal expansion of the cooler can be lowered; and the cooler is easy to dismantle, assemble, and change.

3. An oil-air bucket is provided with jacking rotation, which makes it convenient to repair and maintain.

The oil-air bucket cover is designed with jacking rotation. As all pipelines are in the bucket body, no pipe fittings are on the cover. In this way, relevant repair and maintenance can be conducted conveniently. No matter how big the machine is, one-man operation can be realized.

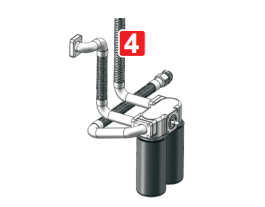

4.A temperature-controlled oil filter base is provided to avoid shutdown caused by jamming.

A flat seal temperature-controlled oil filter base for mixed flows is used to avoid the potential downtime caused by the jamming of the currently adopted divided-flow temperature-controlled piston valve.

5.Ultra-efficient

The compressor is provided with augmented rotors and features a low revolving speed, two-stage compression, a low-pressure ratio, high efficiency, and high reliability. The full range of our air compressors is ultra-efficient now.

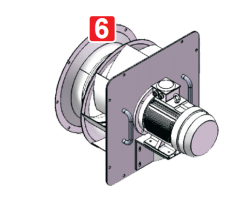

6.A low-speed large-diameter centrifugal blower

The low-speed large-diameter centrifugal blower is simple in structure, can run efficiently and steadily, generates low noise, and shows a good heat dissipation effect. -

Technical Data Sheet

Model

Motor Power

(kW)Discharge Pressure

(Mpa)Discharge Air Flow

(m³/min)Outlet diameter

Dimension

L*W*H(mm)

Weight

(KG)Specific Power

Cooling Mode

QLB37-VV-B-N

37

0.6~0.8Mpa

6.9

G1/2

1780*1185*1690

1270

6.40{KW/(M³/min)}

Air cooling

QLB55-VV-B-N

55

0.6~0.8Mpa

11.5

DN80

2300*1600*2150

2400

6.24{KW/(M³/min)}

Air cooling

QLB75-VV-B-N

75

0.6~0.8Mpa

15.3

DN80

2300*1600*2150

2650

6.08{KW/(M³/min)}

Air cooling

QLB75-VV-G-5-N

75

0.4~0.5Mpa

19.1

DN80

2650*1650*2250

3150

4.89{KW/(M³/min)}

Air cooling

QLB90-VV-B-N

90

0.6~0.8Mpa

19.05

DN80

2650*1650*2250

3125

6.10{KW/(M³/min)}

Air cooling

QLB110-VV-B-N

110

0.6~0.8Mpa

22.6

DN100

3290*1820*2220

3850

5.76{KW/(M³/min)}

Air cooling

QLB110-VV-G-5-N

110

0.4~0.5Mpa

27.9

DN100

2950*1880*2250

4190

4.88{KW/(M³/min)}

Air cooling

QLB132-VV-B-N

132

0.6~0.8Mpa

26.74

DN100

3290*1820*2220

3850

5.95{KW/(M³/min)}

Air cooling

QLB160-VV-G-N

160

0.6~0.8Mpa

32.2

DN100

3660*1920*2220

5180

5.73{KW/(M³/min)}

Air cooling

QLB185-VV-G-N

185

0.6~0.8Mpa

41.4

DN125

3850*2050*2240

5930

{KW/(M³/min)}

Air cooling

QLB200-VV-G-N

200

0.6~0.8Mpa

45.5

DN125

4150*2350*2280

6520

{KW/(M³/min)}

Air cooling

QLB220-VV-G-N

220

0.6~0.8Mpa

51.3

DN125

3950*2190*2250

7950

{KW/(M³/min)}

Air cooling

QLB250-V-W-G-N

250

0.6~0.8Mpa

56.3

DN125

4139*2059*2389

7702

{KW/(M³/min)}

Water cooling

Application cases

Oil Injected Rotary Screw Compressors

Oil Injected Rotary Screw Compressors

Oil Injected Rotary Screw Compressors

Oil Injected Rotary Screw Compressors

Oil Injected Rotary Screw Compressors

Oil Injected Rotary Screw Compressors

Oil Injected Rotary Screw Compressors

Oil Injected Rotary Screw Compressors

Advantage

Application description

Rebar is the common name for hot rolled ribbed steel bars. The grade of ordinary hot-rolled steel bar is composed of HRB and the minimum yield point of the grade. H, R, and B are the first letters of the three words Hotrolled, Ribbed, and Bars respectively. Hot-rolled ribbed steel bars are divided into three grades: Grade II HRB335 (the old grade is 20MnSi), Grade III HRB400 (the old grades are 20MnSiV, 20MnSiNb, 20Mnti), and Grade IV HRB500.

Factory description

Rebar is the common name for hot rolled ribbed steel bars. The grade of ordinary hot-rolled steel bar is composed of HRB and the minimum yield point of the grade. H, R, and B are the first letters of the three words Hotrolled, Ribbed, and Bars respectively. Hot-rolled ribbed steel bars are divided into three grades: Grade II HRB335 (the old grade is 20MnSi), Grade III HRB400 (the old grades are 20MnSiV, 20MnSiNb, 20Mnti), and Grade IV HRB500.

Shipping Packaging

Rebar is the common name for hot rolled ribbed steel bars. The grade of ordinary hot-rolled steel bar is composed of HRB and the minimum yield point of the grade. H, R, and B are the first letters of the three words Hotrolled, Ribbed, and Bars respectively. Hot-rolled ribbed steel bars are divided into three grades: Grade II HRB335 (the old grade is 20MnSi), Grade III HRB400 (the old grades are 20MnSiV, 20MnSiNb, 20Mnti), and Grade IV HRB500.

Why Choose Us?

1)The products can be made completely according to the customer's requirements, and we have our own factory. 2)High quality product and good price. 3)Good Pre-sale、on sale and after sales service. 4)Short delivery time. 5)Exported all over the world, with rich experience.

FAQ

Q:I want a specific size or color. Can I get my color coated steel customized?

Yes. Customization is available. You can choose the color or pattern, size (length, width, thickness, weight, etc.), paints, shape, etc. We offer coils and sheets, as well as further processing services, such as logo printing, etc. Please send us your requirements, we will meet your requirements.

Q: Are we a trader or a manufacturer?

A: We are a manufacturer and have our own factory.

Q: How to pack?

A: Can be packaged according to customer's needs

Q: How long is your delivery time?

A: If the goods are in stock, generally about 25-30days if the goods are not in stock, according to the quantity.

Related Products